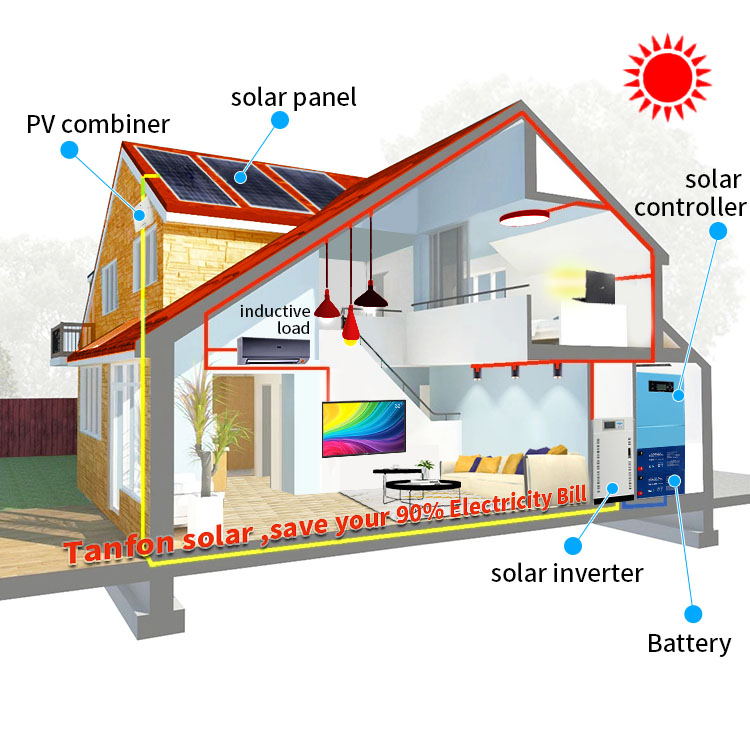

solar power system

90KW Solar Equipments For Home solar panel installation Companies

Product Specification:- Brand Name : TANFON SOLAR

- Model Number : solar system90kw

- DC voltage : 360V

- Output voltage : 110V/220V/360V

- Advantage : German Technology

You May Like

You May Like

Tanfon Supply: Free site survey, design, production, installation, maintenance with our sophiscaticated one-stop service.

Tanfon Solar APP Super Advantage:

1)One Phone remote control ALL solar system

2)Troubleshoot and reduce maintenance costs

3)Develop your brand APP to competitiveness

three phase solar system from 5kw-300kw

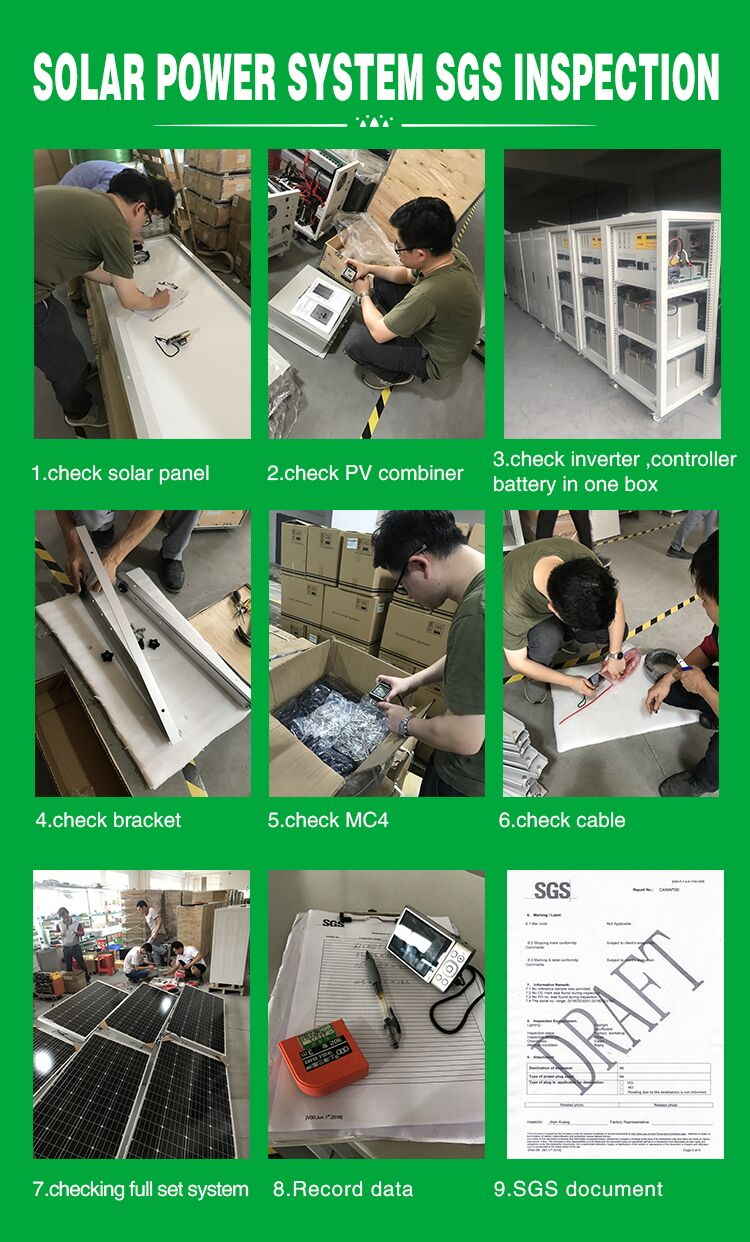

For the products, Each set solar power system has power on&off test 100 times per hour.Each step of production is under strict quality control. Our products are qualified with CE, ROHS, ISO, SGS certification

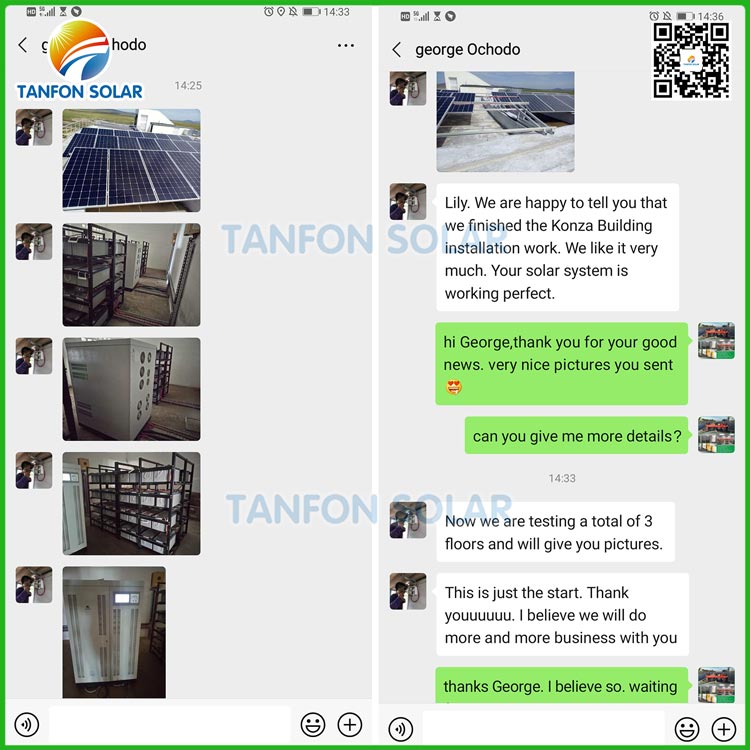

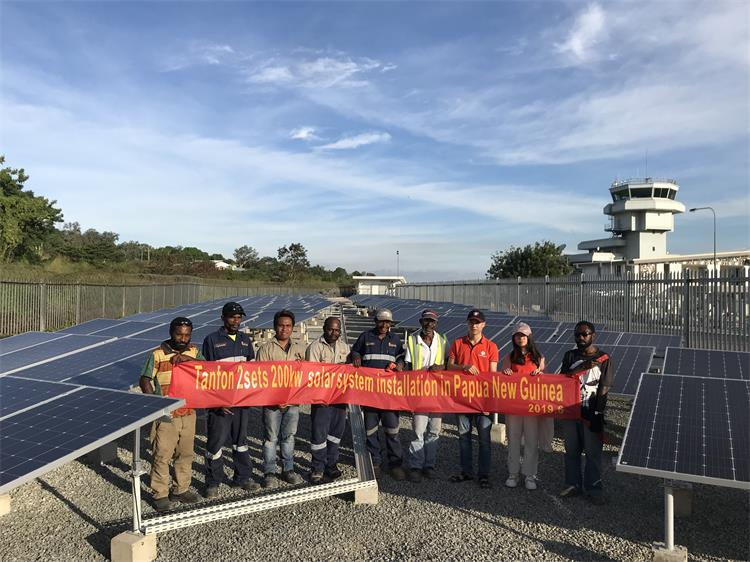

For our project case: Our products have been sold to more than 120 countries, (solar home project,solar school project ,solar hospital project,solar farm project ,solar hotel project,solar air port project ,solar millitary project ,Solar energy water treatment equipment project,solar goverment project etc)

we have a professional installation team, which has been to 32 countries and regions ( Egypt, Bangladesh, Chad, Nigeria,Thailand,Ghana, Doha, East Timor state, Pakistan, kenya ,indonesia ,Dubai,Mozambique etc.) for installation service. We also win many good feedbacks from the customers.

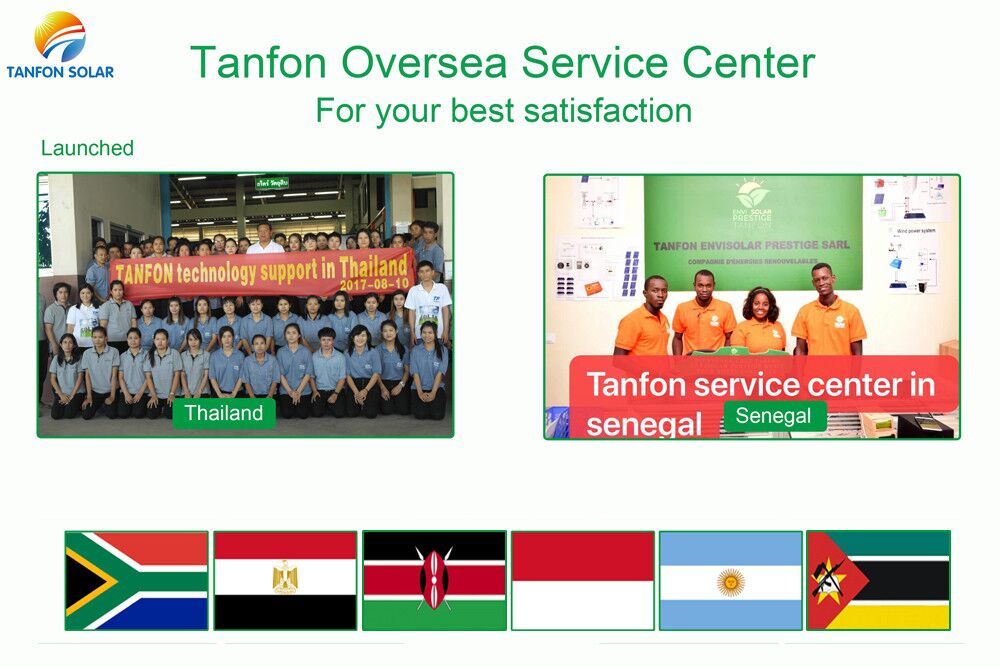

For our Global service in Thailand,Kenya,Senegal,Mozambique,will build 120 service centers all over the world. Give strong after-sales service in Local

| 90KW Solar Equipments For Home solar panel installation Companies | ||

|

FS380w solar panel | 260pcs |

| H10T PV combiner | 2pc | |

| 360V/150A solar controller | 2pc | |

| TF90KW three phase inverter | 1pc | |

| 2V/1000AH gel battery | 180pcs | |

| solar panel rack | 1set | |

| Battery cable+PV cable | 1set | |

| Packaging Information | Total volume:52CBM Total weight;16852KG | |

| Installation area | solar panel:520m² inverter+battery:20-60m² | |

|

FS380W mono solar panel(poly optional) Vmp:38.39V Voc:47.13V Imp 9.75A Size : 1956*992*40mm 25 years life time (CE TUV) Coated steel Glass:3.2mm Tem pered Terminal block:IP65 with MC4 connector Efficiency performance :25 years 80 % 20 year 85% 10 years 90% Connect:each 13pcs in series, 4strings in series |

|

PV combiner Model:H10T-360v Multiple PV strings inputs Simplify wiring between PV array and controller, protections to controller , Wide range of DC input voltage Reliable thunderstorm& surge protection |

|

|

MPPT controller model: 360V/150A Charging efficiency; 90%-95%, charging mode, intelligent control., various protection functions; Can read daily,monthly and total power generation |

|

|

Solar three phase Inverter power:SC90kw/360v WiFi signal receiving module Low voltage:324V High voltage:442V, Charging efficiency; 90%-95%,with AC charger built-in, Protection against short-circuit, Output: 380V 415V 50/60HZ |

|

|

Solar battery 1)Gel battery,2 years warranty. ship NEW for service. 2)Lithium battery,3 years warranty. ship NEW for service. |

|

|

Slope Rooftop or Flat rooftop including complete fittings wind load:55m/s,snow load:1.5kn/m2 structure:Anodized Aluminum+stainless steel, Angle adjustable |

|

1)84pcs 25mm2*35CM battery cable 6pcs 25mm2*2M battery cable 25mm *30M 2)4mm2 PV cable 400M,16mm2 cable 50M 3)terminals and MC4* 10pairs, air breakers |

| How to control solar power system(solar panel) quality? 90KW Solar Equipments For Home solar panel installation Companies | ||

| System | System Essentials | Pictures |

|

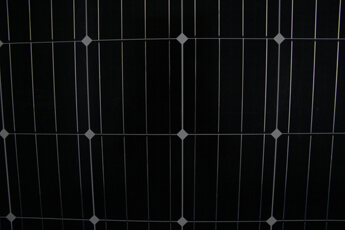

Supply System |

1. Solar cell: Dark color, black, no color difference 2. Solar Cell shape: corner piece 3. Solar cell efficiency: 21% |

|

|

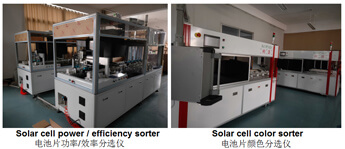

Production System |

1. Classification of solar cell with different colors, powers and efficiencies using automatic sorting equipment 2. EL test of the solar cell by EL device to ensure that the solar cell is not cracked 3. Components are fully automated production line operations |

|

| QC System |

1. EL tester tests the solar cell to ensure no cracks 2. The component tester performs EL and data testing before component packaging to ensure data is acceptable and components are not cracked. 3. Component products are monitored with data from a tester to ensure data is correct |

|

|

Packaging System |

1. Can be packed in carton box or wooden cases 2. The solar panel is in an upright packaging mode to reduce the transport breakage rate |

|

| Factory Inspection System | QC inspection qualified products, distinguish the identification zone placement, ensure the shipment quantity, model, customer name is correct. | |

| After Sales Service System | Free replacement of new solar panel during the 10-year warranty period if have any quality problem. | |

Solar panel production video: Classification of solar cell with different colors, powers and efficiencies using automatic sorting equipment

| How to control solar power system(Solar Inverter) quality? | ||

| System | System Essentials | Pictures |

|

Supply System |

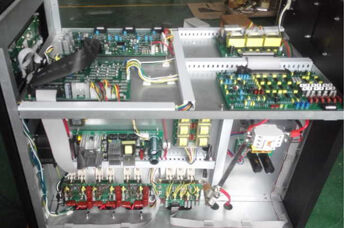

1. Since the establishment of our inverter factory, we have been purchasing transformers and capacitors from the same supplier. 2. MOS tube adopts imported IR brand 3. SCR adopts imported from Germany 4. IGBT adopts Japanese Mitsubishi brand |

|

|

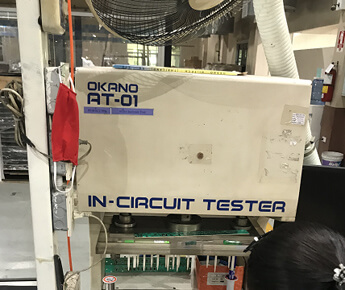

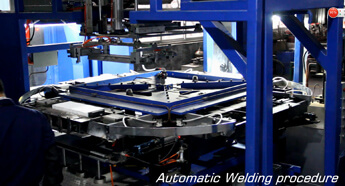

Production System |

Wall-mounted inverter board production uses automated machine plug-ins. Improve efficiency, reduce loss, and enhance stability |  |

| QC System | ICT test, pinhole alignment PCB board, check all lines, reduce the failure rate. |  |

|

Packaging System |

Power lower than 1KW inverter carton packaging, containing pearl cotton; power higher than 2KW inverter plywood wooden box packaging, containing pearl cotton. One piece one packaging. |  |

| Factory Inspection System | Our inverter has passed 100 times of ultimate power-off test. According to statistics, 99% of the tested inverter can work very stable. |  |

| After Sales Service System | All inverters are free to send new spare boards within the warranty. For more services, please click the link to view. | |

Solar inverter board production: use automated machine plug-ins. Improve efficiency, reduce loss, and enhance stability.

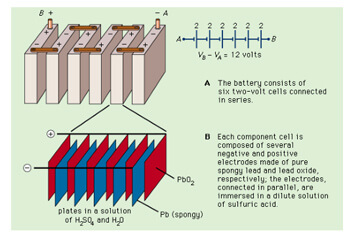

| How to control solar power system (Gel Battery) quality? | ||

| System | System Essentials | Pictures |

|

Supply System |

1. Battery case, ABS material conforming to UL94HB and UL94V-0 standards, no color difference, no crack. 2. The unique lead-calcium grid improves the hydrogen evolution potential, reduces gas evolution, reduces corrosion rate, and extends battery life. 3. The use of copper terminals, excellent conductivity and high wear resistance, enhances high current discharge performance; 4. High quality AGM partition for partition

|

|

|

Production System |

1. Battery plate production workshop, independent production of positive and negative plates, effectively ensuring the quality of the plates 2. Semi-automatic cladding machine): Semi-automatic double-layer cladding technology, double-layer separator can better prevent short circuit of the pole plate. The semi-automatic double-layer board process ensures that the packaged groups are neat, beautiful and clean. 3. Automatic slotting machine: higher efficiency, saving the process involved in manual slotting, avoiding the human contact group, maximizing the protection of the pole group, making the battery have very good self-discharge performance, battery consistency, total Voltage consistency.

|

|

| QC System |

1. DC spectrometer: high precision detection of lead purity to ensure purity above 99.994% 2. High current detector: ensure that each battery is under high current, whether charge and discharge normal 3. Large battery tester: Under high current, whether the bus bar of the battery has a problem of melting and short circuit 4. Internal resistance meter: Make sure that the internal resistance and voltage of each battery are normal, and the consistency of the battery.

|

|

|

Packaging System |

Carton packaging, use the inspection-free pallet to hold the shipment |  |

| Factory Inspection System |

QC inspection qualified products, distinguish the identification zone placement, ensure the shipment quantity, model, customer name is correct |

|

| After Sales Service System |

Free replacement of new batteries during the 2-year warranty period if have any quality problem |

|

Factory inspection:

Tanfon solar certification:

Solar system application: